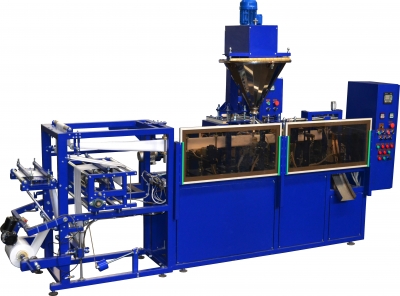

Packing machine for sachets AF-35

Filling machine for appointments for organizing non-stop packaging in a bulk way of dosing sawn-off, good-flowing, effervescent products (zukrovy powder, medical and cosmetic powders, pepper, spices, etc.) "sachet" (sachet-package) of polymeric pliers (polypropylene, duplex, triplex, lam.papyre).

The automatic machine is folded from a horizontal packing machine and a volumetric screw dispenser.

The automatic packing machine operates in a horizontal position, which structurally allows you to remember the different sizes of your packages, as well as to dispense products with a minimum number of doses into a package, which allows you to accurately measure the doses and accurately seal all the seams of the package.

The automatic machine is folded from a horizontal packing machine and a volumetric screw dispenser.

The automatic packing machine operates in a horizontal position, which structurally allows you to remember the different sizes of your packages, as well as to dispense products with a minimum number of doses into a package, which allows you to accurately measure the doses and accurately seal all the seams of the package.

Find out the price

Media

Image Gallery

View the embedded image gallery online at:

https://upack-tech.com/en/equipment/fasovochnoe/item/852-fasuvalnyi-horyzontalnyi-avtomat-iz-shnekovym-dozatorom-af35sgh#sigProId1bec4899e8

https://upack-tech.com/en/equipment/fasovochnoe/item/852-fasuvalnyi-horyzontalnyi-avtomat-iz-shnekovym-dozatorom-af35sgh#sigProId1bec4899e8